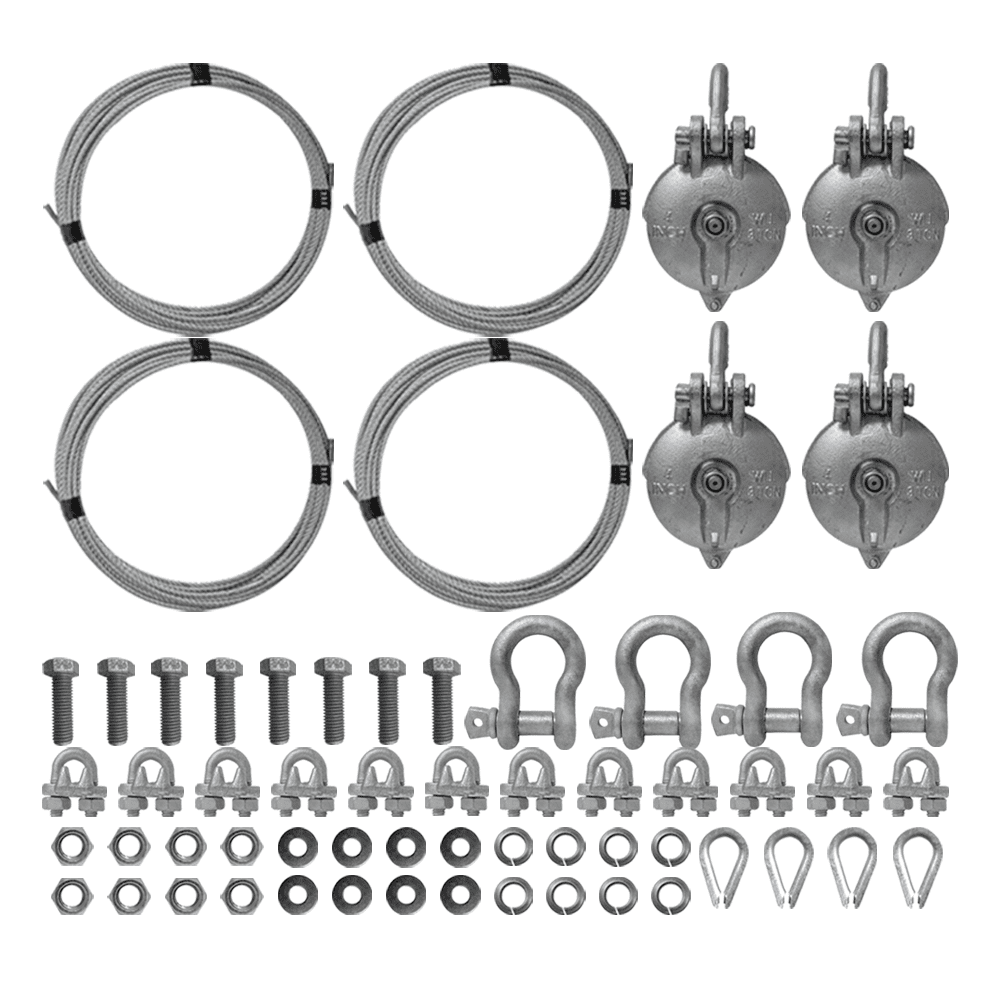

10K-12K Galvanized Pile Mount Cable Installation Kit

The 10K-12K Galvanized Pile Mount Cable Installation Kit includes galvanized cable, snatch blocks, screw pin shackles, and galvanized fasteners. Fits the 10,000 lb. and 12,000 lb. BH-USA galvanized pile mount boat lifts.

Kit Includes:

(4) 5/16 in. x 31 ft. galvanized 7 x 19 aircraft cable

(12) 5/16 in. galvanized malleable wire rope clips

(4) 5/16 in. galvanized wire rope thimbles

(8) 5/16 in. galvanized nuts

(4) 4 in. 3-ton snatch blocks

(4) 5/8 in. x 3.25 ton galvanized screw pin shackle

(8) 5/16 in. galvanized flat washers

(8) 5/16 in. galvanized lock washers

(1) 10K-12K 4 post pile mount lift guide

Any boat heavier than 6,000 lbs. needs the boat lift cable to be compounded. We use the ASME (American Society for Mechanical Engineers) recommended safety factor and rating system. The same is used in the overhead crane industry. Never use “Breaking Strength” for rating a cable.

Aircraft Cable

Aircraft cable is specified by the number of strands in the rope times the number of wires in each strand. “7 x 19” means the rope has seven (7) strands, with 19 wires in each strand. 7×19 is the most flexible aircraft cable construction.

BH-USA recommends 7 x 19 aircraft cables for boat lift applications. Always consider at least a 5:1 safety factor when figuring working loads. Use a minimum of 4 drops when using in boat lift applications. A test certificate for all cables sold by BH-USA is available upon request.

7 x 19 aircraft cable is not suitable for use in aircraft controls. Never lift humans with 7 x 19 aircraft cable.

Safe Working Load vs. Minimum Breaking Strength

It is important to use the Safe Working Load (SWL) of the cable and not the breaking strength when selecting wire rope. The breaking strength is just that… the amount of force a brand-new wire rope can hold in a perfect world where if you put one more pound on it would cause it to SNAP!

Why don’t we use the breaking strength?

The breaking strength of wire rope was tested using a machine that isolates just the wire rope so that the end connections do not affect the overall strength. In the real world, the wire rope is a system of components including the wire rope itself and the end connections working together dynamically which have to bend around sheaves and cable winders and are only as strong as the weakest link. The minimum breaking strength is simply a measure of how much tension the wire rope can withstand in a perfect scenario that does not take into consideration the other factors that reduce the capacity of the wire rope system in a boat lift.

Why is the rating so low?

The Safe Working Load includes a safety factor (SF) to allow for all the things that can happen to wire rope during its useful life that will reduce the breaking strength. The safety factor is a recommendation from the American Society for Mechanical Engineers (ASME) for this type of equipment such that the lift can still safely hold the load when some or all factors working to break the wire rope are present. The safety factor gets “used up” as the wire rope deteriorates effectively lowering the breaking strength. In the next steps, we will determine the loads that each wire rope will be exposed to and then will choose a wire rope size with an SWL rating higher than the maximum loads.

Specifications

| Lift Size | 1 Part Straight Line | 2 Part Compounded |

| 2,800 lbs. | 3/16 in. | 3/16 in. |

| 4,500 lbs. | 1/4 in. | 3/16 in. |

| 6,000 lbs. | 5/16 in. | 1/4 in. |

| 9,000 lbs. | X | 1/4 in. |

| 10,000 lbs. | X | 1/4 in. |

| 13,000 lbs. | X | 5/16 in. |

| 16,000 lbs. | X | 3/8 in. |

| 24,000 lbs. | X | 3/8 in.* |

The first step in deciding what size wire rope is required for your lift is to determine the total weight to be lifted which will include the “wet” weight of the boat, the maximum estimated cargo that could be put in the boat during the lift, and the weight of the lifting cradle

- Boat

- Fuel

- Water (Ballast, live well, potable, etc.)

- Any cargo items in the boat (Note: There should never be people in the boat while being lifted.)

- Boat cradle and bunks

The boat weight specified by a manufacturer is typically the “dry” weight of the boat. To get the “wet” weight, you must include the weight of the fuel (gasoline is 6.30 lb/US gal and diesel is 6.94 lb/US gal), the weight of any water (8.34 lb/US gal) that may ever be present in the boat and the estimated weight of the possible cargo (ie – coolers, skis, etc.).

Cable Ratings

| Cable Size | Cable Material | Lifting Capacity | Min. Breaking Strength | Safe Working Limit | Best Water Type |

| 3/16 in. | Stainless | 1,050 lbs. * | 3,700 lbs. | 925 lbs. | Saltwater |

| 3/16 in. | Galvanized | 925 lbs. * | 4,200 lbs. | 1,050 lbs. | Freshwater |

| 1/4 in. | Stainless | 1,750 lbs. * | 6,400 lbs. | 1,600 lbs. | Saltwater |

| 1/4 in. | Galvanized | 1,600 lbs. * | 7,000 lbs. | 1,750 lbs. | Freshwater |

| 5/16 in. | Stainless | 2,450 lbs. * | 9,000 lbs. | 2,250 lbs. | Saltwater |

| 5/16 in. | Galvanized | 2,250 lbs. * | 9,800 lbs. | 2,450 lbs. | Freshwater |

| 3/8 in. | Stainless | 3,600 lbs. * | 12,000 lbs. | 3,000 lbs. | Saltwater |

| 3/8 in. | Galvanized | 3,000 lbs. * | 14,400 lbs. | 3,600 lbs. | Freshwater |

* – Use a minimum of 4 drops for boat lift applications

NOT FOR LIFTING HUMANS

No product can operate indefinitely at its rated capacity. Wire rope and Cable must be inspected regularly for any deterioration which may result in the loss of original strength. Users must determine whether further use of the rope would constitute a safety hazard to life or property. Lubricate operating ropes regularly. Keep out from under any raised loads and keep out of the line of force of any load.

AVOID SHOCK LOADS.

Due to the uncontrollable situations in which this cable is used after the purchase, BH-USA cannot warranty or be held liable for cable past the purchase date. It is the responsibility of the ultimate user to determine a working load limit for each application. Many factors should be considered: included among, but not limited to, loads applied, speed of operation, acceleration or deceleration, length of rope or cable, shock loads, abrasion, corrosion, number, size, condition, and location of drums and sheaves, facilities for inspection, and the danger to life and property should a rope or cable break. Wire Ropes and Cables must be stored, used, lubricated, and maintained in accordance with normal safety standards; and must be properly designed, maintained, and operated. Inspect regularly.

Do not kink, knot, or crush. Do not ever use wire rope sold by or made by BH-USA to lift humans in any way.

Product Overview

- 5/16 in. x 31 ft. aircraft cable

- 4 in. 3-ton snatch blocks

- 5/8 in. 3.25-ton screw pin shackle

- All galvanized components

Related Products

You may also like...

-

Aluminum Pile Mount Top Beam Bracket

$73.75 – $86.65 Select options